- Home

- Manufacturing capability

- Product

- R&D Center

- About

- Contact Us

- Data download

Tel:0530-6339701

With the support of a professional team engaged in basic research and application research, the company has successively undertaken the research tasks of national development and Reform Commission, Ministry of science and technology, provincial and municipal major projects and industrialization projects, and obtained a number of research results and invention patents in the field of magnesium, covering high strength, heat resistance, low temperature, corrosion resistance More than 30 kinds of high toughness and flame retardant magnesium alloys meet the needs of aerospace, rail transit, automobile, machinery, military and other industries.

In the 21st century, human beings put forward new requirements for metal structural materials: the research and development of new materials should not only be able to adapt to the development of high technology and meet the needs of human beings' high-quality life, but also require rich resources, high efficiency, low energy consumption and easy recovery, which is conducive to sustainable development; it must be able to meet the increasingly stringent requirements of environmental protection laws and regulations in the future to enter the market and application smoothly.

China is a big country of magnesium resources. We should take advantage of this condition, improve the value of magnesium resources, adjust the industrial structure, expand the application of magnesium and lead the development of magnesium industry...

| NAME |

Element % |

Room temperature Tensile properties |

|||||||||

| Al | Zn | Mn | Si | Fe | Cu max | Ni max |

Re Total |

Tensile strength MPa |

Yield strength MPa |

Elongation % |

|

| AM60B | 5.6-6.4 | 0.20max | 0.26-0.5 | 0.50max | 0.004max |

0.008 max |

0.001 max |

- | 240 | 130 | 6-8 |

| AM50A | 4.5-5.3 | 0.20max | 0.28-0.5 | 0.5max | 0.004max |

0.008 max |

0.001 max |

- |

230 | 125 |

6-10 |

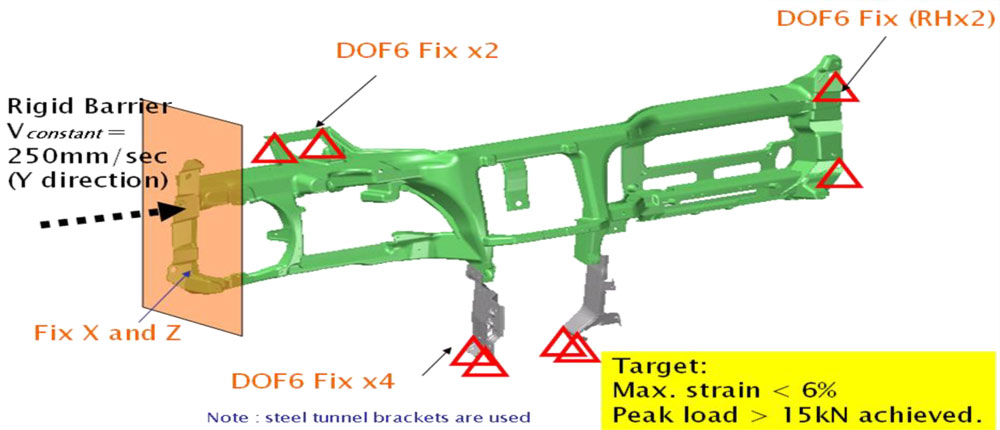

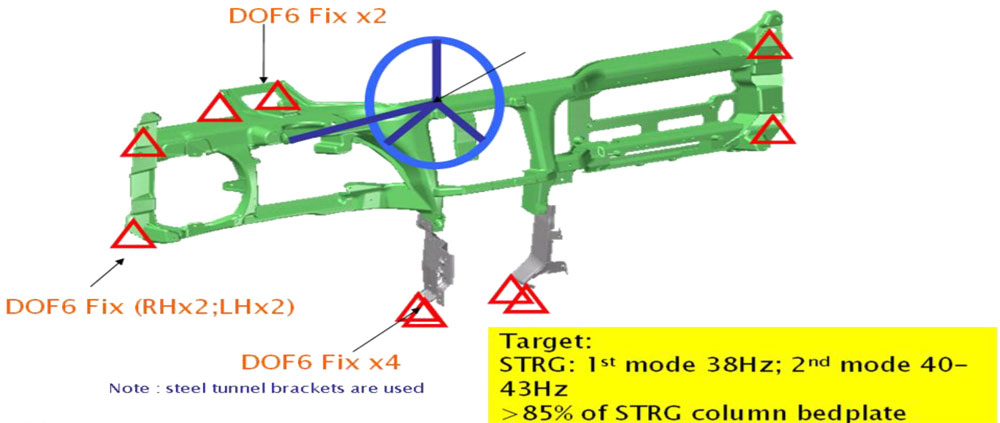

| LOAD Case | Target | |

| 1 |

1.1 Column Stiffness(V) 1.2 Column Stiffness(L) |

500 N/mm 750 N/mm |

| 2 |

PSAB Loading 2kN *2 (up and down) |

Stress <= 130MPa (YS) |

| 3 | Knee Loads(4kN*4) | No failure |

| 4 | Side Impact Loading | Peak load > 15kN |

| 5 | ODB Loading | Peak load > 8kN |

| 6 | NVH |

>38Hz? 85% of column? |

| Weight | <5kg |

The company's testing center has complete testing equipment, including spectrometer, universal tensile testing machine, online ultrasonic flaw detector, metallographic testing machine, three coordinate measuring machine, salt spray testing machine, electronic Brinell hardness tester, X-ray flaw detector, which can provide analysis, testing and evaluation of chemical composition, mechanical properties, technological performance, nondestructive testing, microstructure and other items of raw materials and products, For the company's technical research and development and product quality testing to provide a perfect testing platform.

鲁公网安备 37172902372310号

Technical support:QIANHE